AQUATIC LIFE SUPPORT OPERATIONS

INSIDE THE PUMPHOUSE: Twin 16 inch intake lines feed three 50hp pumps that supply water at 2000 gallons per minute!

Aquatic animal life support operators are the water quality and mechanical system professionals that move the water, design and maintain the systems, develop and distribute the products that make aquatic animal and plant care and display possible. Life support systems are found in any aquarium, amusement park, museum, or research facility that holds or displays aquatic organisms.

UNE’s Marine Science Center is unique in that it is one of few marine research institutions housing a state-of-the-art flowing seawater system. Located at the mouth of the Saco River, the MSC provides 24/7 flowing seawater to house marine flora and fauna for research and educational purposes.

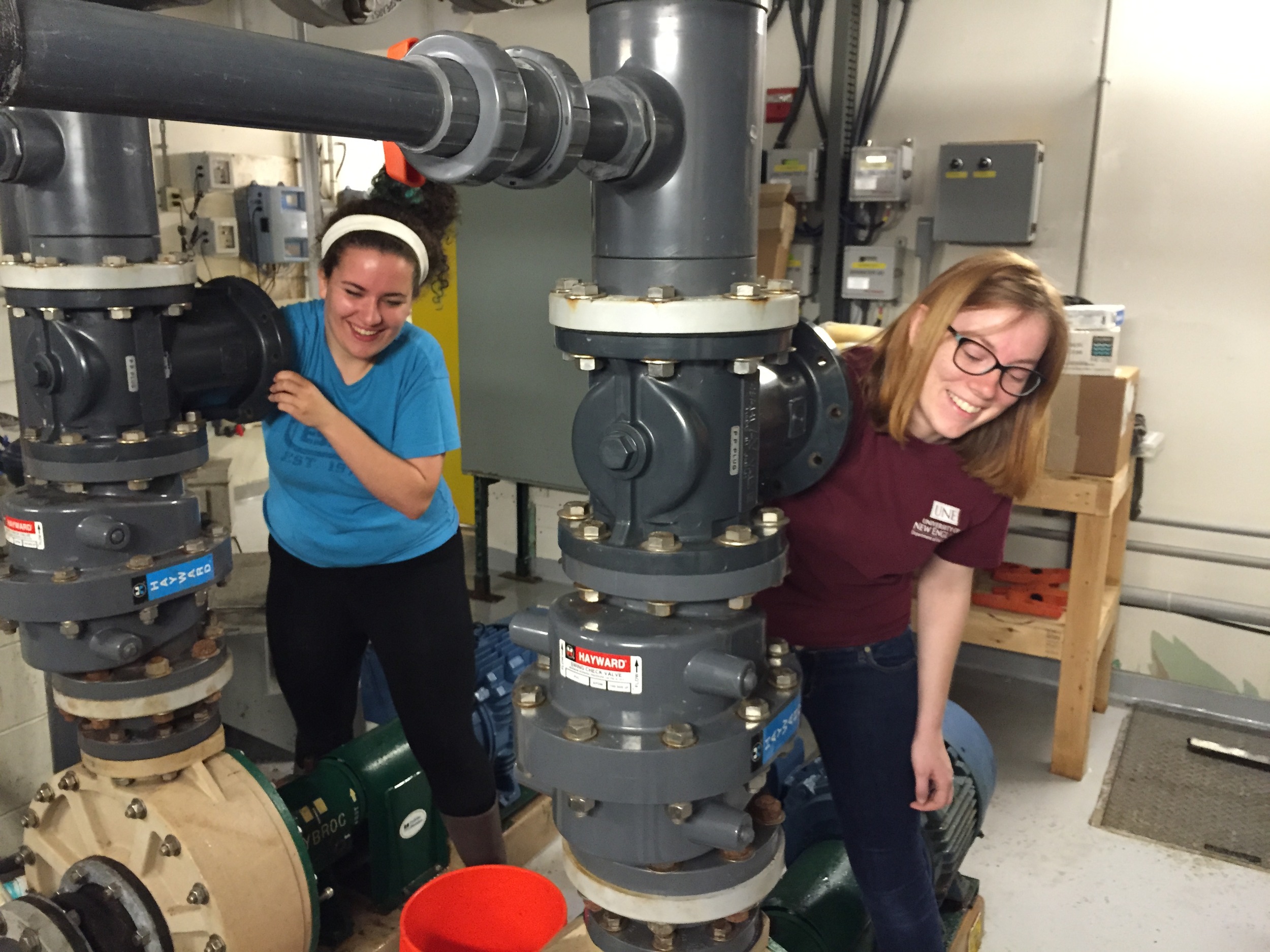

Giant pillow valves supply and drain the storage tank.

The seawater system is easily capable of flowing one million gallons of water each week at at rates of up to 200 gallons per hour. Tidally situated, the automated seawater system only pumps seawater during high tides and relies on a 460,000 gallon storage tank for water between tides.

Stored seawater is supplied to the MSC primarily via gravity flow leading to a head tank that provides seawater pressure throughout the facility. All seawater that is pumped into the facility is returned back to the to Saco River making the MSC’s operations very similar to that of a wastewater treatment plant.

Water returning to the Saco River is often cleaner than the seawater taken in due to the scrubbing properties of the biofouling community in the system’s pipes and tanks. Maintaining the system and its operational continuity is critical for keeping marine critters alive.

The next time you are watching fish swim, plants sway, or a hippopotamus bathe in water, you’ll know there’s a life support operator who made that experience possible.

The water storage tank is 50' in diameter and 32' tall and holds nearly a half a million gallons of water. On an average day, the facility uses about 100k gallons. The balance of the water was held as a reserve in case of power failure or if low salinity conditions are present at pump time.

The storage tank has been drained in preparation for pressure washing, line jetting, and vacuuming. The big red truck is a vacuum truck that captures and transports the rinseate offsite.

Cleaned in the Spring and Fall, the extent of sediment and fouling are driven by nature and vary annually. Note the difference in wall panel color. The white panels have been pressure washed, the brown panels are waiting to be cleaned. On the right, a water jetter is inserted into one of two supply lines that lead to the MSC.

Note how bright the walls are. The concrete structure at the rear of the tank is where seawater enters form the pumphouse. The naval bronze screens on the right protect the supply lines that feed the MSC. Naval bronze is used because it has anti-fouling properties and is resists corrosion in seawater.

Water leaving the storage tank enters the MSC in the pump room. It contains two 15hp assist pumps that kick in when storage tank head pressure is unable to meet water demands in the facility. Water passes through the pumproom and is driven into the head tank on the second floor.

The header and pumps in this room foul too. It is quite arduous to clean and rebuild the entire header in a single day so every six months we alternate which parts of the line to dismantle and clean.

Unlike the storage tank, the pipes of the seawater system have lots of nooks and crannies for critters like these sea salps (aka giant booger worms) to settle. It is necessary to clean them out because they can greatly reduce a pipe's capacity.

Water jetting and a wet vac do most of the work, but there are tight spots that only skinny arms can reach.

Located on the second floor, the 2,500 gallon head tank supplies water pressure to the entire facility. Filter bags capture large solids and help minimize plugging in the progressively smaller plumbing found throughout the facility.

Tanks in the MSC range from 10 gallons to 10,000 gallons and are all different shapes. Seawater is delivered 24/7 throughout facility and allows year-round maintenance of indigenous specimens.

Flowing seawater is also distributed the classrooms where it helps maintain live specimens for lab and lecture.

Water tables hold specimens for lab coursework and also function as touch tanks for outreach. Their small plumbing terminations require a lot of attention or else they quickly plug with sediment.

Donated by a local lobsterman, the blue lobster is a big hit for visitors. Makes you think twice about where you put your hands.

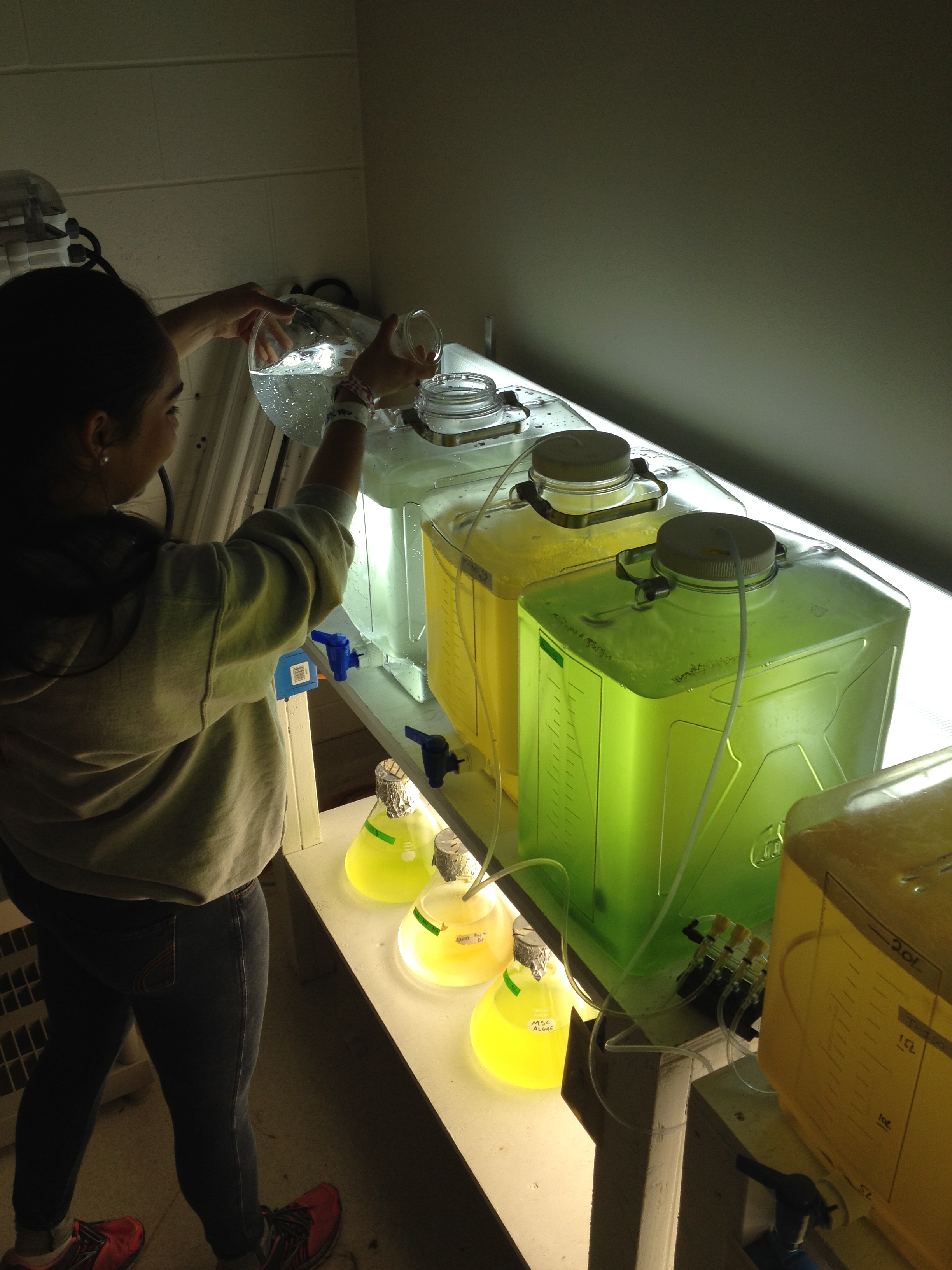

Sterilized seawater is used to start phytoplankton cultures. The small culture systems are cultivated into larger batches for experimental diet work in shellfish aquaculture research.

Phytoplankton starter cultures are transferred to larger 200L K-tubes for grow out. Developed in-house by students and staff, the LED lights, aeration, and plumbing all comprise essential elements of innovative phytoplankton life support!

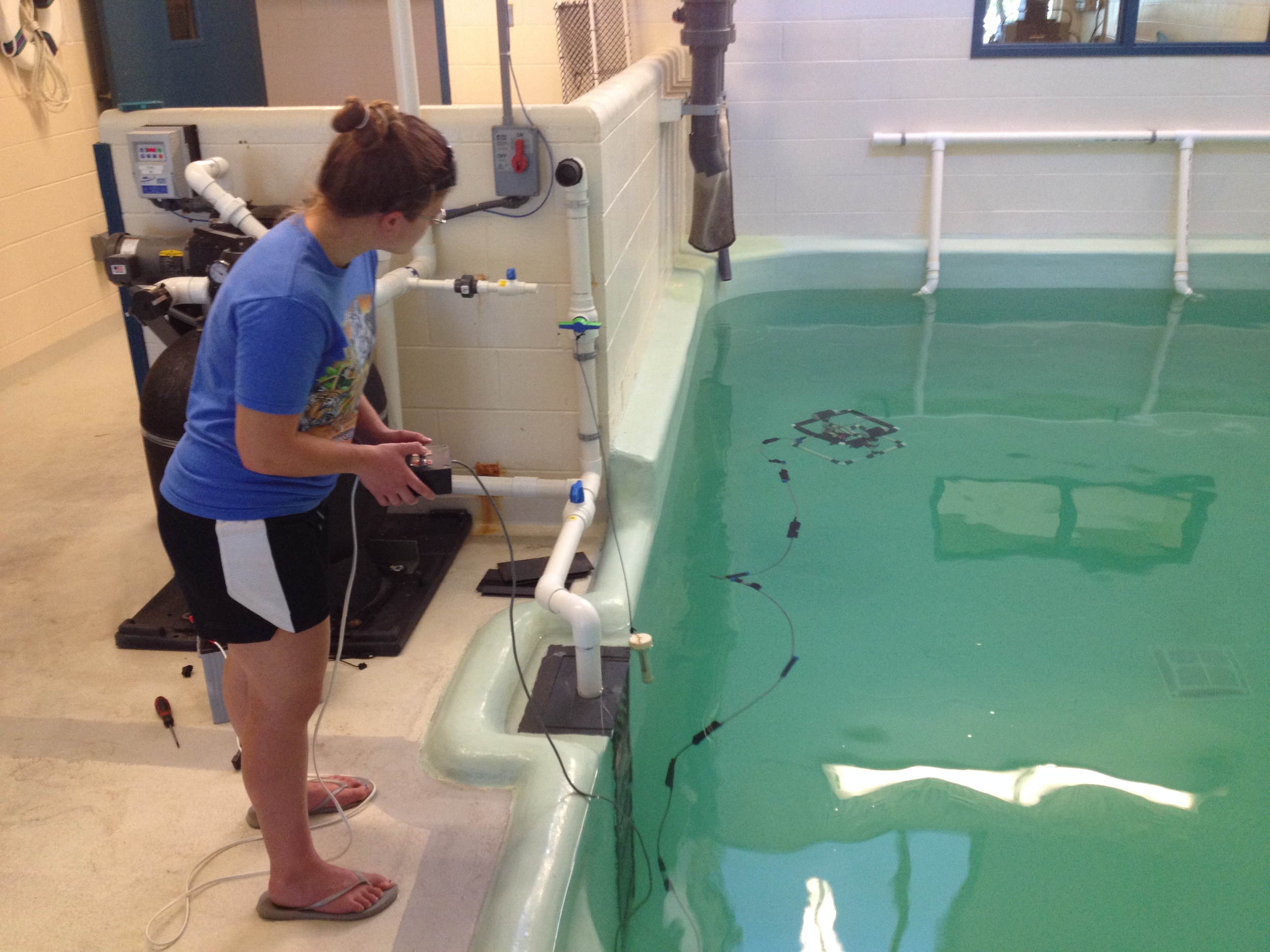

Larger indoor pools allows testing of oceanographic instrumentation and in this case, it gives a student a chance to test drive a remotely operated vehicle (ROV).

Since all of the water used by the MSC is returned to ocean, there are strict safeguards in place, like this composite sampler, that help uphold environmental responsibilities. In most cases, discharged water is actually cleaner that what is initially taken in.