Drill Press Restoration

A Craigslist ad for a Delta drill press that was sold 'just before I arrived’ serendipitously lead me to these two beauties. The generosity and kindness of some personal internet hero’s helped me save these machines, one of which is now complete and became the first machine in my own shop.

I share this story to offer up my sincerest thanks and respect to some of my internet hero’s who’s YouTube videos and knowledge sharing helped make this project possible: Tom Lipton of Ox Tool Co, Keith Rucker of Vintage Machinery, and Lisle ‘Tubalcain’ Peterson of MrPete222.

———

A retired pipefitter from Maine’s largest naval yard was liquidating his homestead in Maine in order to relocate to Ohio to be with his grandchildren. After swapping some shop talk and noticing my disappointment in the missed connection with the Delta drill press, he invited me to tour the remainder of his two-story garage and shop.

The first floor of his garage was his metalworking and 'oily area’. The second floor was his ‘clean area’ that housed a beautiful woodworking shop full of machinery, decades of lovingly built projects, and a forest view from a picture window that only a woodshop in Maine could afford.

Tucked away in the corner of the woodshop sat two sawdust covered Walker-Turner machines that looked like siblings. The grandfather confided they were special antique projects he was waiting to restore but never got around to. He was clear that they were not for sale and were also Ohio-bound.

After more shop talk and mutual machinery admiration, we began to part ways and I wished him a safe relocation.

“They can’t be split up. You have to buy them both.”, I heard from over my shoulder. In some cosmic change of heart, the grandfather made me an offer that I couldn't refuse. The grandfather confided that he wasn’t the most mechanical person and the machines needed some love. “Pipefitters specialize in straight things, not machinery”, he told me and proceeded to ask if I’d like to buy them both.

I beamed with excitement and immediately started to inspect both machines. The bandsaw ran, but rattled badly as it was partially dismantled. The drill press let out an unhappy whir and I quickly turned it off. My excitement diminished further as I indicated the chuck and found a runout of 0.025 thousandths. My ears, my measurements, and my brain told me to run, but my gut told me to stay as there were no obvious signs of abuse. After some discussion and encouragement from my significant other, I took a gamble.

Disassembly revealed that the machine had been assembled incorrectly, explaining the unhappy noise it made. The press did not have a serial number plate not it, but I believe it to be a Walker-Turner 700 series dating to the late 20’s or early 30’s. I’ve still yet to find any Walker-Turner machine with a similar amber knob on the handle.

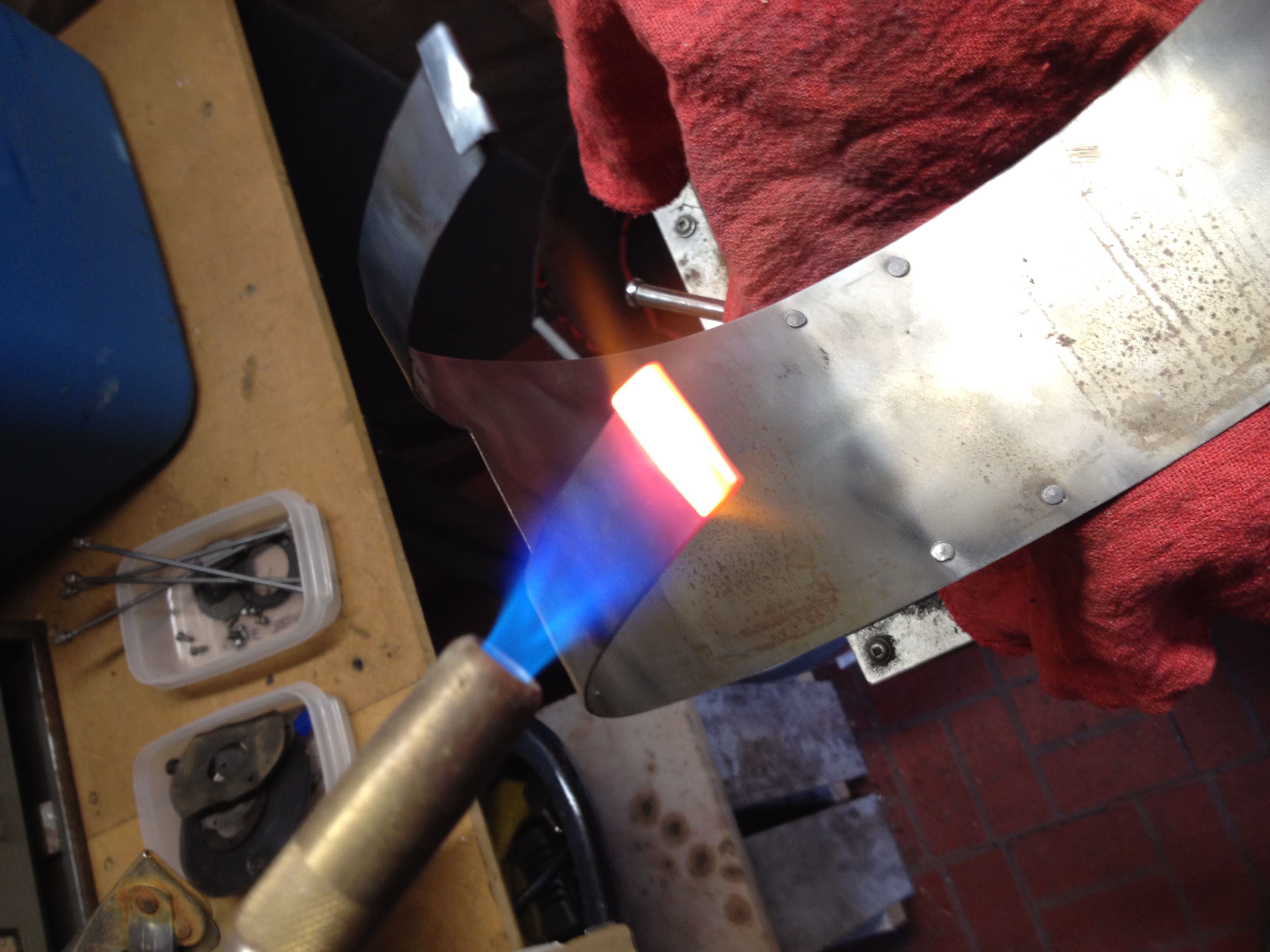

The morse taper on the chuck was buggered up and with lots of of TLC, I was able to reduce the runout. The motor was fully rebuilt and shroud required some metalsmithing. The work surfaces were lapped, and all the bare metal polished accordingly. The bearings were repacked and purred with a soft hum. The paint color I chose is not a traditional color, but still deserving of a classic machine. All in all, I ended up with a very useable press that someone else can rebuild in another 80 years…and its way classier than the Delta that brought me there.

Admittedly I am eager to start on the bandsaw. But it had to wait, as I just had to stop and say ‘Thank You’ before I went any further.