Advanced Technology and the Entrepreneurial Spirit

Automation & Production Technology Program

THE PLAN - Luckily there was a plan in place for layout and some of the furniture and robotics equipment had been selected. Decisions about electrical, data, and air drops were next.

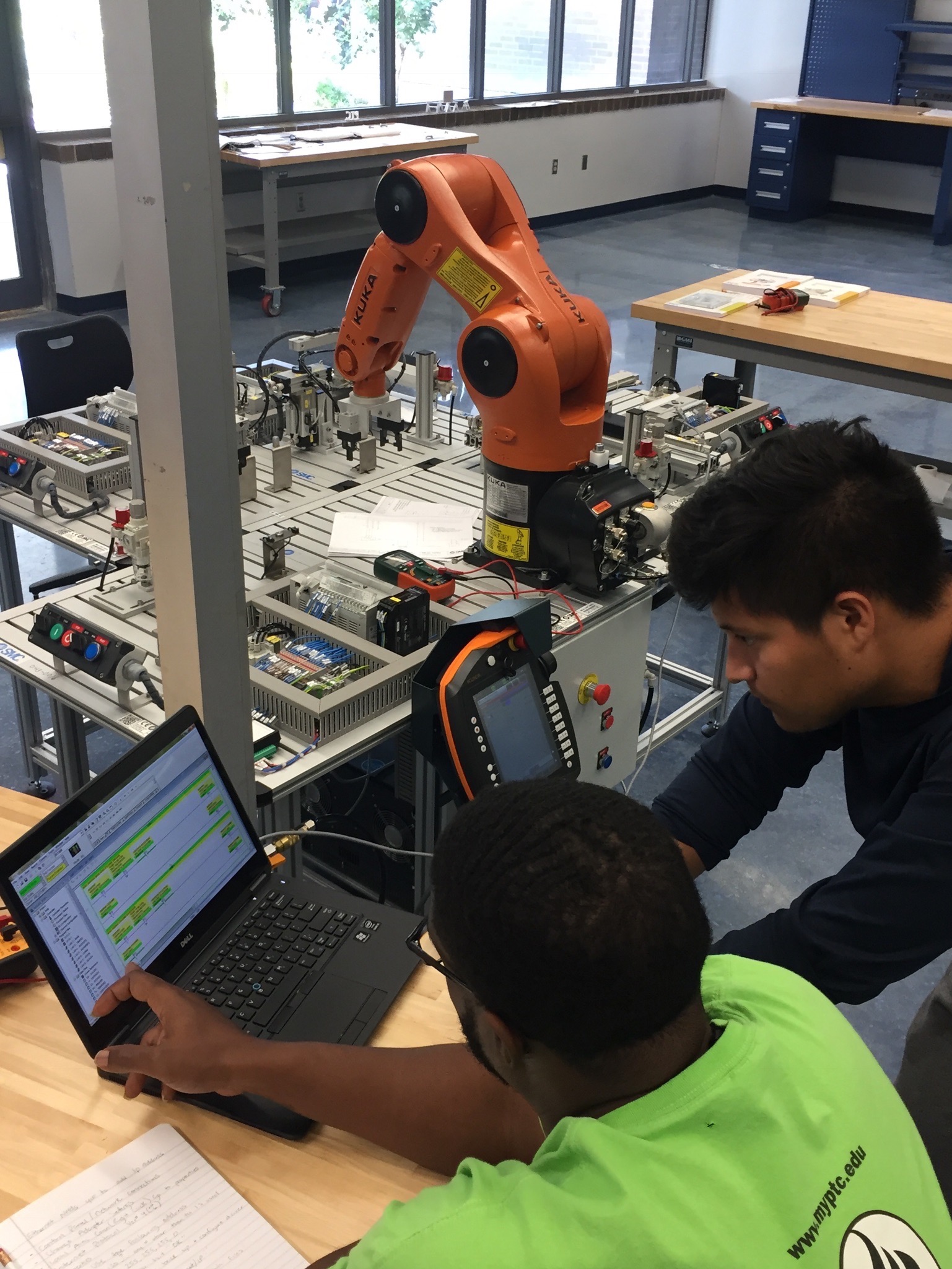

The Automation and Production Technology program was launched at Pinellas Technical College to support workforce development needs of the high-tech manufacturing industry.

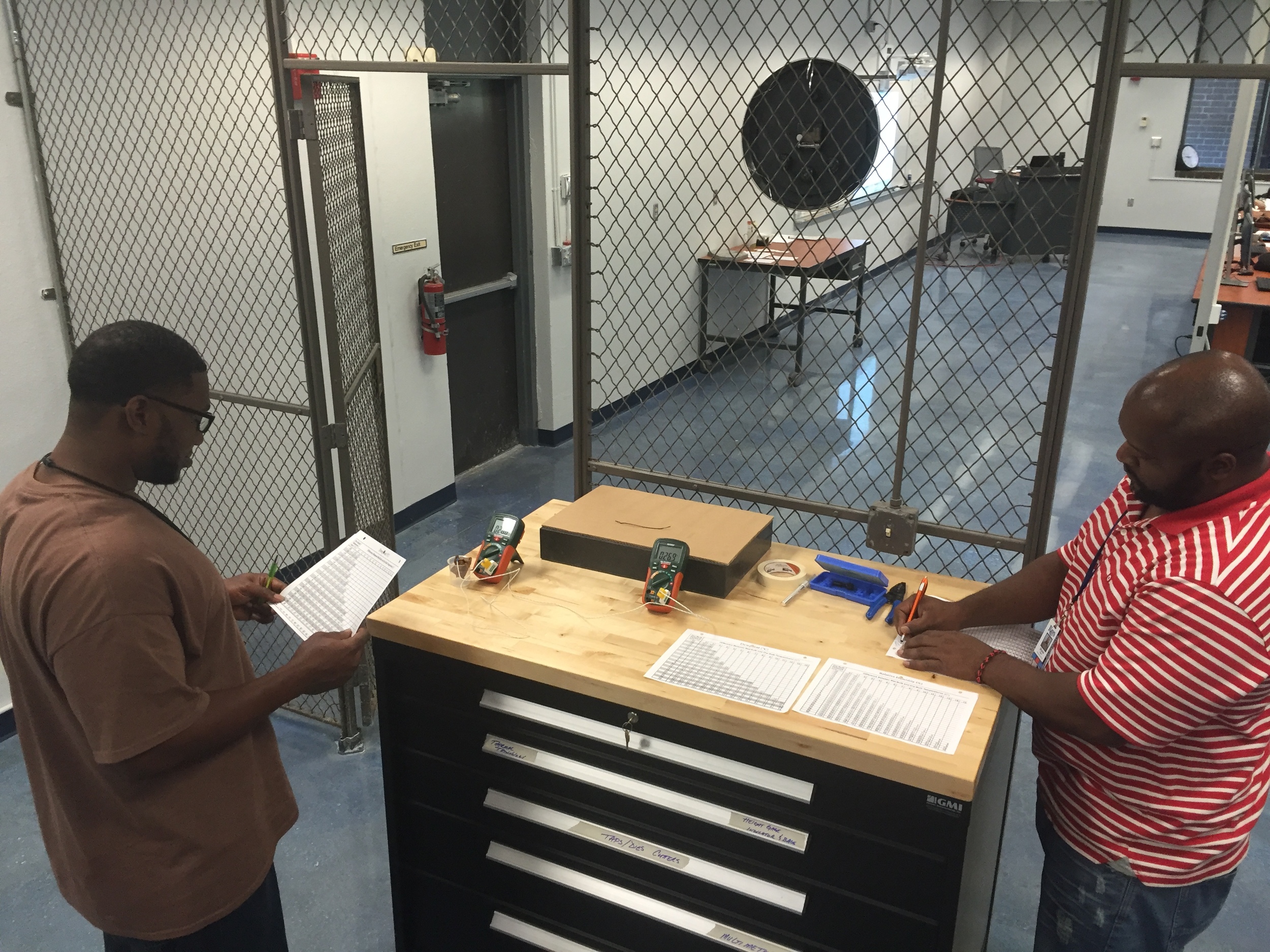

The goal of the program was to provide students with the essential and foundational skills required to to operate, maintain, and troubleshoot modern automated systems. This necessitated that students understand automation's characteristic subsystems such as electricity, pneumatics, hydraulics, and programmable logic controllers. Students also learned to be adept at using multimeters, reading schematics, using hand tools, and operating machine shop equipment.

WE MADE IT - It took six months, but things came together and the inaugural students finally got to experience the robotics that they came for.

At only 600 contact hours, the program was short but intense, covering 22 different technical and career readiness standards.

The program was unique in that it provided options for direct entry into the workforce; was aligned for direct enrollment into adjacent technical programs; provided eligibility for industry credentialing as Certified Production Technicians through the Manufacturing Skill Standards Council; and qualified students for engineering articulation credits in the Florida College System.

GROUND ZERO - Startup projects are fun in that they are challenging, but planning and logistics can easily fall behind. When I arrived on my first day, the classroom was still a storage area and students were on the way. All I could do was put on my creative thinking cap and find ways to move forward.

PROGRESS - The room was emptied, the linoleum floorign was removed, and the concrete slab sanded in preparation for polishing.

NEW FLOORS - Polished concrete was chosen for durability and economy and also required minimal upkeep.

BIG BLUE - The glossy blue floors dramatically brightened up the room and are representative of today's modern and clean manufacturing environments.

We were able to occupy the classroom while finishing touches were still being put on. The 5000sqft space was set up into three areas: a computing and lecture area, a robotics and equipment area, and a workshop to keep the clean work separate from the dirty work!

BEFORE

AFTER