Sea Turtle Life Support System (2013)

Overview of the new turtle suite with 10,000 gallon main pool (right) and quarantine tank (left).

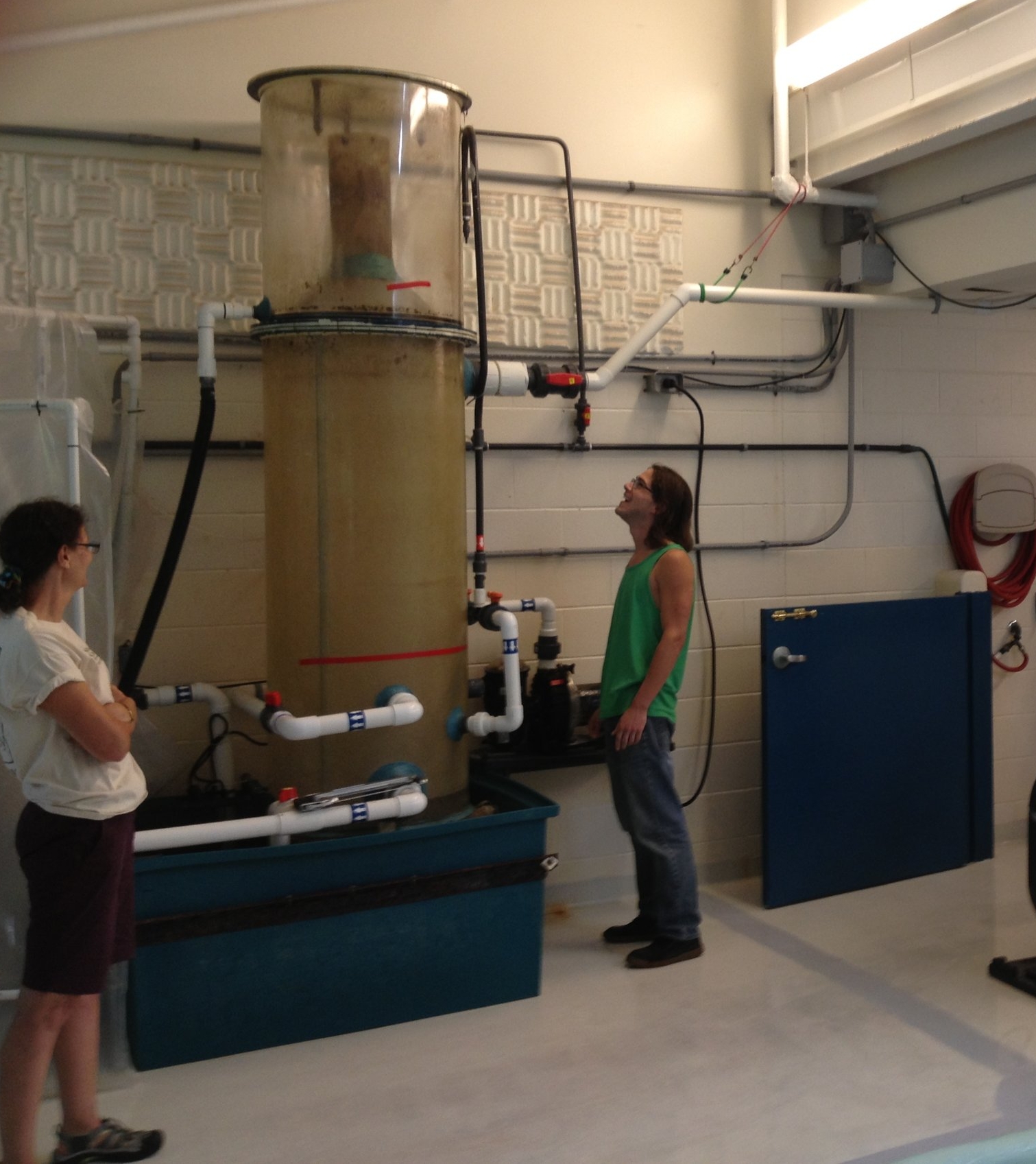

Way off the ground! The old protein fractionator installation was unstable and difficult to maintain.

Science: During summer months, sea turtles travel north along the Atlantic seaboard. They follow warm Gulf Stream currents northward of Cape Cod, MA in search of food and favorable water temperatures. In the fall, water temperatures drop and the cold blooded turtles begin a southward migration in search of warmer, tropical waters. As they navigate south, some turtles encounter the hook of Cape Cod, and become trapped by the geographical land barrier.

Turtles trapped in the Cape Cod bay quickly succumb to cold air and water temperatures. They exhibit diminished biological functions, disorientation, and confusion - a state referred to as cold stunned. Cold stunned turtles wash up on Cape Cod shores where they strand and rapidly decline in cold and freezing air temperatures.

Originally installed above the biofilter to save space, the protein fractionator was hard to reach, the plumbing was not intuitive, and the system was very intimidating to animal care staff.

Stranded sea turtles are rescued, and if given a warm place to heal and recover, can be rehabilitated. Rehabilitation centers use recirculating life support systems to house the turtles, keeping them warm and comfortable and giving them a place to swim. Successfully rehabilitated turtles are transported to warmer climates for release back into the wild.

There are seven species of sea turtles world wide; six of those species reside in US waters. Since all sea turtles in US waters are listed as endangered, rescue and rehabilitation efforts help to make every turtle count!

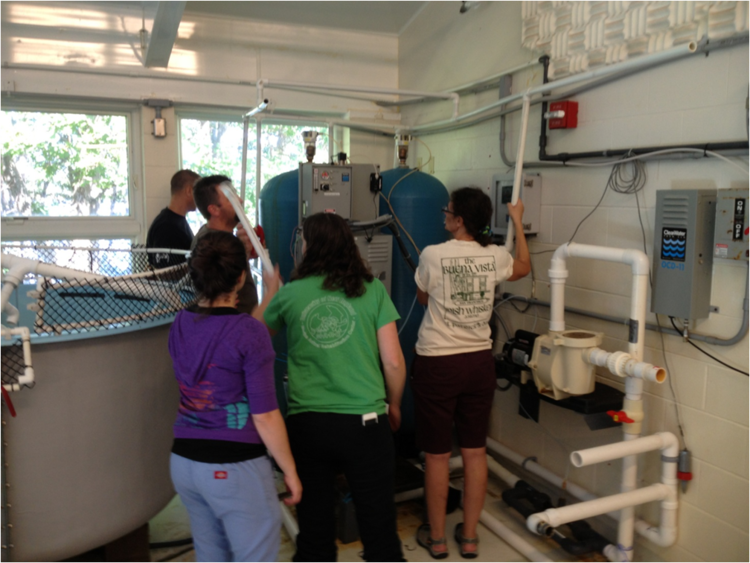

Technology: The sea turtle life support system was a redesign and refit project. I led an interdisciplinary team of operators, animal care technicians, an intern, and an aquaculture researcher all of whom contributed to the input and construction of the new system.

Housed at the Marine Animal Rehabilitation and Conservation program at the University of New England Marine Science Center, the original sea turtle system consisted of a sand filter, protein skimmer, biofilter, ozone system, and boiler. The system resided in a dedicated turtle suite and fed a 7,500 gallon pool, subject to high levels of biomass and consequent loading.

The old ozone system, a.k.a. the bubble room.

System age and the corrosive marine environment resulted in the original system’s deterioration and diminished overall functionality. A compromised ozone system raised safety concerns as well. The system relied on three different sized centrifugal pumps, was balanced by ball valves, and had numerous float switches. The entire system was very difficult to operate, balance, and understand for the animal care team. It also required extensive upkeep and suffered from regular failures.

The new design repurposed a sand filter, boiler, and protein skimmer, with all other components being either re-engineered or purchased new.

The ozone system was replaced with a UV light system. As the system resides in an educational setting and is utilized by students and volunteers, the UV system’s increased safety features offset any ozone advantages.

Most of the the new plumbing and all electrical work was done by our facility operator. Clean, minimalist plumbing made the system more intuitive to the animal care staff who oversaw its daily operation.

Dismantling the old ozone system.

Two new identical1.5HP centrifugal pumps with variable frequency drives added efficiency as well as precise and easy system balancing; their strategic placement eliminated the need for a third pump. New waterproof electrical enclosures and breakers were also added.

A new biofilter with spray bar was constructed from a reclaimed 500 gallon plastic drum. An external sight glass with float switch and overflow were built into its side. The single float switch was tied to a digital delay timer and prevents the pumps and UV filter from running dry.

A salvaged diatomaceous earth filter was installed between the biofilter and the UV system to aide in the UV’s efficacy.

The new system has been running since October ’13. All of the new features have delivered the anticipated improvements, including ease of use. The DE filter has proved a bit challenging as it clogs more frequently than desired. It is taking some time to understand how to maintain the amount of media, but we have found that running the DE filter without media works very well.

The turtles are really happy too!!! MARC was able to take in five loggerheads this year. As of February ’14 they are all successfully rehabilitated and awaiting release back into the wild!

The newly engineered system (r to l): Sand filter with VFD controlled pump, protein fractionator, biofilter with automated level sensing and flow control, diatomaceous earth filter, and UV sterilizer.

Dismantling the old ozone system.